Cutting CO2 emissions by turning flare gas into a valuable energy source with membranes

PuraMem® VOC membrane turns flare gas into valuable energy.

- PuraMem® VOC membrane turns flare gas into valuable energy

- Reducing CO2 emissions in the oil industry

- Supporting World Bank initiative to end routine flaring by 2030

Marl/Essen, Germany. By offering its innovative PuraMem® VOC membrane separation technology for flare gas recovery, Evonik enables the energy industry to cut CO2 emissions and supports the World Bank's “Zero Routine Flaring by 2030” initiative.

Turning flare gas from emissions into a valuable energy source

Oil production generates significant amounts of associated gas that is, wherever possible, used as an energy source because oil companies and governments have made substantial investments to capture it. Nevertheless, a considerable amount of the gas is flared because of economical or technical challenges. Associated gas is often very heavy, hydrocarbon rich (i.e. high C3+ content) and cannot be used at the well head. According to the Global Gas Flaring Reduction Partnership, thousands of gas flares at oil production sites around the globe burn approximately 140 billion cubic meters of natural gas annually, causing more than 300 million tons of CO2 to be emitted to the atmosphere.

Evonik’s PuraMem® VOC membrane separation technology offers a safe and efficient way to process such heavy gas with the lowest operating cost of any available technology. The membrane separates heavy hydrocarbons as natural gas liquids (NGL), water and hydrogen sulfide and generates a clean gas stream that can be used to generate power without flaring. The recovered NGL can be converted to liquefied petroleum gas (LPG).

“Our innovative membrane technology enables today's energy industry to increase efficiency and reduce emissions at many single processing points. The sum of the applications results in attractive sustainability benefits for the industry," says Dr. Iordanis Savvopoulos, Head of the Fibres, Foams and Membranes Product Line at Evonik.

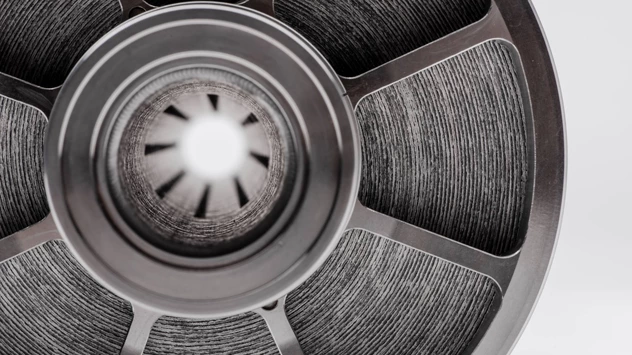

PuraMem® VOC stands for a robust, spiral-wound membrane which is based on Evonik’s high-performance polymer. It features a stable performance over long time periods under challenging operating conditions. PuraMem® VOC has been specially designed with the flexibility to be seamlessly retrofitted in the existing infrastructure. The standard dimension of an 8” diameter and the flexible adapter system makes it possible for PuraMem VOC to easily plug-in as a drop-in replacement to the existing system installations.

Technology to support the World Bank's “Zero Routine Flaring by 2030” initiative

The World Bank's “Zero Routine Flaring by 2030” initiative commits governments and oil companies to end routine flaring by 2030. The main objective is to support cooperation between all relevant stakeholders so that solutions to gas flaring can be successfully implemented through appropriate regulation, application of technologies, and financial arrangements.

Company information

Evonik is one of the world leaders in specialty chemicals. The company is active in more than 100 countries around the world and generated sales of €12.2 billion and an operating profit (adjusted EBITDA) of €1.91 billion in 2020. Evonik goes far beyond chemistry to create innovative, profitable and sustainable solutions for customers. About 33,000 employees work together for a common purpose: We want to improve life today and tomorrow.

About Smart Materials

The Smart Materials division includes businesses with innovative materials that enable resource-saving solutions and replace conventional materials. They are the smart answer to the major challenges of our time: environment, energy efficiency, urbanization, mobility and health. The Smart Materials division generated sales of €3.24 billion in 2020 with about 7,900 employees.

Disclaimer

In so far as forecasts or expectations are expressed in this press release or where our statements concern the future, these forecasts, expectations or statements may involve known or unknown risks and uncertainties. Actual results or developments may vary, depending on changes in the operating environment. Neither Evonik Industries AG nor its group companies assume an obligation to update the forecasts, expectations or statements contained in this release.